Objectives : At the end of this exercise you shall be able to

• desoldering components from PCB using desoldering pump

• desoldering component using desoldering wick.

Requirements

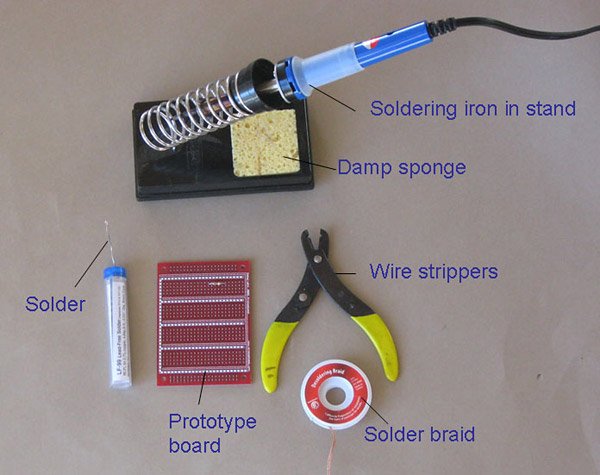

Tools/Equipments/Instruments

• Trainees tool kit

- 1 Set • Soldering iron, 25W

-1 No

• Desoldering pump (plunger type)

- 1 No

• Heat sink plier - 1 No

Materials/Components

• Desoldering wick - as reqd

• Cleaning solution (IPA) - as reqd

• Flux - as reqd

• Cleaning Brush - 1 No

• Safety goggles

- 1 No

• Crocodile clip

- 1 No

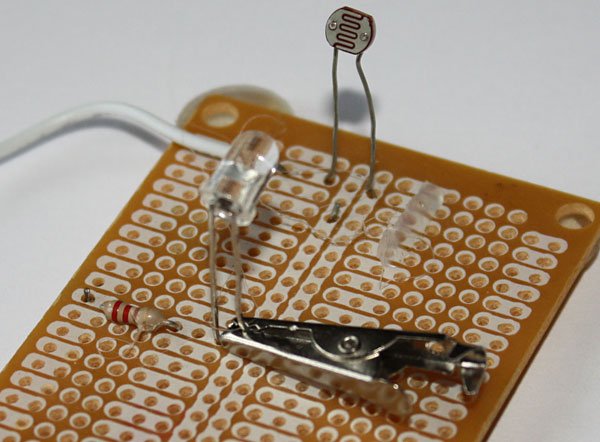

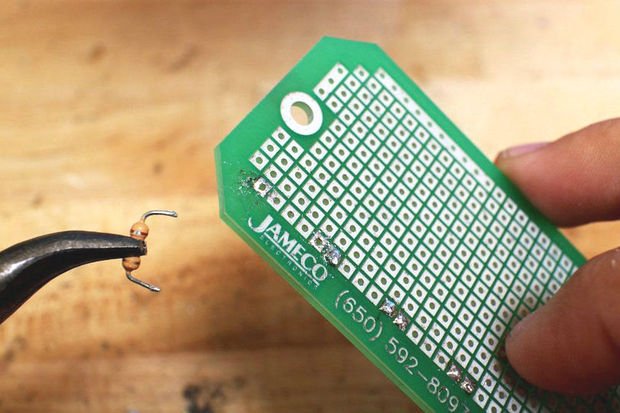

• Assembled PCB board for

Desoldering work - as reqd

DESOLDERING

From using desoldering irons to sketchily knocking breadboard components off on the side of a table, there are tons of ways to remove components from a circuit board. Desoldering is an important skill to learn once you've gotten the hang of soldering, because messing up a soldering job isn't improbable.

- This process is the removal of solder and components from a circuit board for troubleshooting, repair, replacement, and salvage.

- It is the reverse process of soldering.

- It is a process of removal of solder and components mounted on circuit boards.

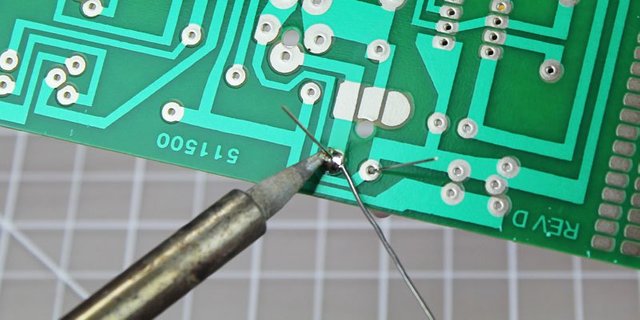

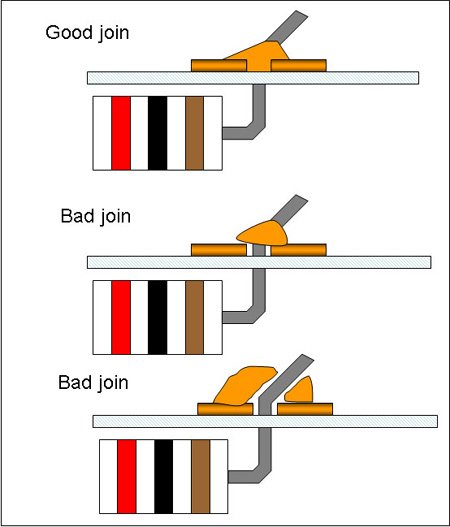

- The soldered joint is removed by the process of desoldering. For this purpose a small vacuum pump is used to remove solder from the plated through holes.

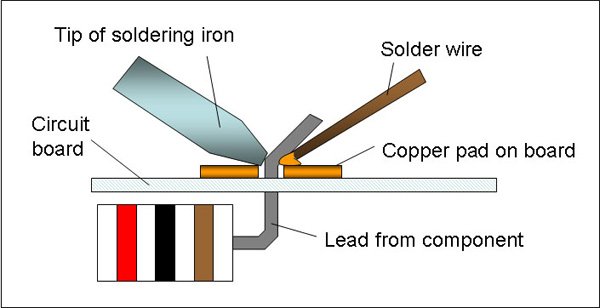

- The lead over which the desoldering tip was placed is moved in a circular motion for rounded leads and back and forth for flat leads

Desoldering Basics

Materials Needed for Desoldering

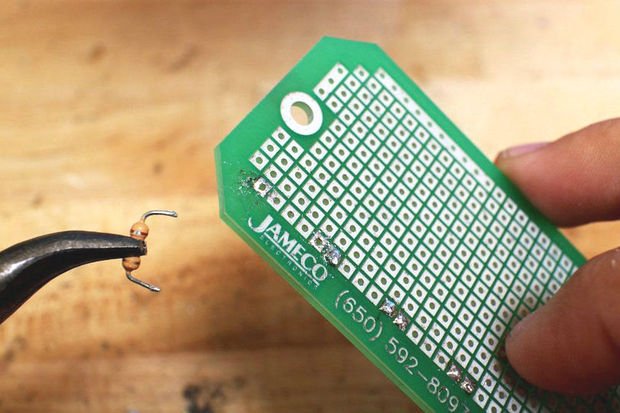

a. Solder Sucker/ Desoldering Pump

The most commonly used and convenient equipment needed for desoldering is the desoldering pump. A good manual solder sucker like this one works pretty well for selectively removing through holes parts from a PCB. Cheaper and smaller units do not work as well. They're marketed as compact but they don't works as well due to the limited stroke length and smaller cylinders.

The most commonly used and convenient equipment needed for desoldering is the desoldering pump. A good manual solder sucker like this one works pretty well for selectively removing through holes parts from a PCB. Cheaper and smaller units do not work as well. They're marketed as compact but they don't works as well due to the limited stroke length and smaller cylinders.Desoldering Process

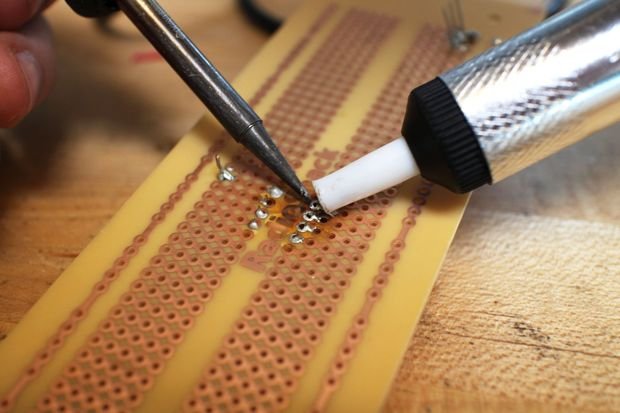

One of the nicest ways to desolder a component involves using a desoldering pump. A desoldering pump is essentially a small, high pressure vacuum. After heating up the solder, you can use the desoldering pump to suck the solder up and out of the way. Here are the basic steps for using a hand-powered desoldering pump:

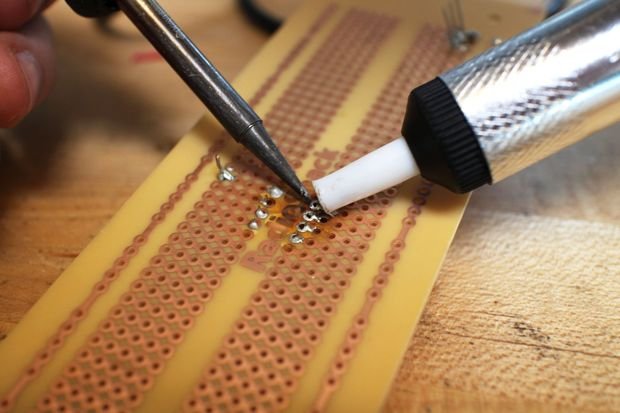

1. Heat up the solder you want to remove with a soldering iron (some desoldering pumps also come with attached irons).

2. Press down on the plunger (If your pump has a bulb, just squeeze the bulb).

3. Once the solder is molten, place the tip of the desoldering pump against the solder that you want to remove.

4. Release the plunger or bulb. Some desoldering pumps have a release button so that you don't have to hold it the whole time.

5. Remove free component.

6. Repeat steps 1-4 to remove any excess solder.

7. Dispose of the solder inside the pump by repeatedly pressing down and releasing the plunger.

.jpeg)

.jpg)